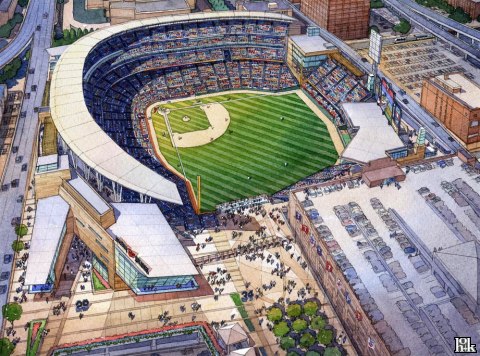

Stadium & Downtown Minneapolis. Officials commissioned a steam line yesterday that runs from the Minneapolis Hennepin Energy Recovery Center (HERC) to the new Twins stadium and downtown Minneapolis district heating system run by NRG Energy. HERC is a waste-to-energy facility located in downtown Minneapolis. HERC uses mass burn technology to convert 365,000 tons of garbage a year into electricity (producing enough each year to provide power to the equivalent of 25,000 homes) that is sold to Xcel Energy, Inc.

Stadium & Downtown Minneapolis. Officials commissioned a steam line yesterday that runs from the Minneapolis Hennepin Energy Recovery Center (HERC) to the new Twins stadium and downtown Minneapolis district heating system run by NRG Energy. HERC is a waste-to-energy facility located in downtown Minneapolis. HERC uses mass burn technology to convert 365,000 tons of garbage a year into electricity (producing enough each year to provide power to the equivalent of 25,000 homes) that is sold to Xcel Energy, Inc.

The 1,600-foot line will heat and cool the new stadium and downtown buildings using steam. Steam from Hennepin Energy Recover Center has been used to generate electricity, but diverting some of the steam for direct cooling and heating is more efficient.

What is it? Cogeneration, or combined heat and power, is the simultaneous production of electricity and useful heat from the same fuel or energy. Facilities with cogeneration systems use them to produce electricity, and use the waste heat for process steam, hot water heating, space heating, and other thermal needs. District heating systems deliver heat through pipes to a certain zone for residential and commercial heating requirements. Fuels commonly used include natural gas, oil, diesel fuel, propane, coal, wood, wood-waste and other biomass.

In Minnesota. There are combined heat and power sites all over Minnesota (see a list of most of them and a few more here). There are opportunities for expansion of existing combined heat and power and district energy systems, and for many of them to switch from coal and fuel oil to less carbon intensive fuels like biomass.

- District Energy provides biomass-fueled hot water district heating and cooling services to much of downtown St. Paul, while at the same time producing electricity.

- New Ulm and Virginia are examples of cities in Greater Minnesota who have their own combined heat and power plants that were built several decades ago and still serve large percentages of their populations.

- St. Paul, Rochester, and Albert Lea have combined heat and power integrated into their wastewater treatment facilities.

- Rahr Malting in Shakopee, the largest single site malt producer in the world, recently partnered with the Shakopee Mdewakanton Sioux Community (SMSC) to create a biomass-to-energy project called Koda Energy that generates electricity and heat by burning agricultural byproducts and grown energy crops on the Rahr Campus—Rahr will use the heat to offset their natural gas use, and SMSC will sell the electricity to their customers.

Moving Forward. Minnesota also has opportunities for moving forward with combined heat and power in hundreds of communities with organic waste or thermal production industries that currently let much of their steam escape into the air, and their hot water into our lakes, rivers and streams—that’s like heating your home and then leaving a window open, or running water in a shower with nobody in it! Steam and hot water are resources that we can be using to create electricity and for heating and cooling.

Learning More. For those with an interest in learning more, check out the 1996 Opportunities to Expand Cogeneration in Minnesota and the 2001 Inventory of Cogeneration Potential in Minnesota. Also, the Midwest Combined Heat and Power Application Center in Chicago is the Midwest’s premier center for technical assistance on CHP, such as determining the feasibility of CHP at a particular site. Check their website for CHP evaluation tools.